Optimise your generator’s performance with these key maintenance tips. For professional support or more complex needs, our engineers are here to help—contact us today.

Regular generator maintenance is essential to ensure reliable power supply and prevent costly downtime. With scheduled generator maintenance services, businesses can avoid unexpected failures, extend equipment lifespan, and enhance performance. Following generator maintenance tips, such as checking oil levels and filters, helps identify minor issues before they become major problems. Timely generator repair and maintenance also reduce operational risks. For businesses seeking generator maintenance UK, professional support by GCM ensures compliance with safety standards and optimises performance.

With any generator you should always follow the recommendations and inspection and maintenance schedules provided in the manufactuer supplied handbook. Check the state of the generator daily and immediately arrange for the replacementof any worn or damaged parts. This blog contains a sample maintenance schedule, inspection and maintenance procedures that could be performed in order to help you take good care of the generator. Other maintenance activities that may be more complex or that require special tools should not be attempted without first consulting a specialist generator maintenance company, such as ourselves.

The following are the main safety precautions which the user must comply with. However, since it is impossible to include all the dangers that could arise during maintenance, remember that the decision whether an operation is to be performed is strictly personal. Comply with the following precautions when performing maintenance on the generator:

Verify there is no water or condensation infiltration

Verify the tightness of the cables and components

Internal cleaning of the electric boards and control panel.

Visually check the condition of the equipment and devices

Check the condition and/or replace the electric wires

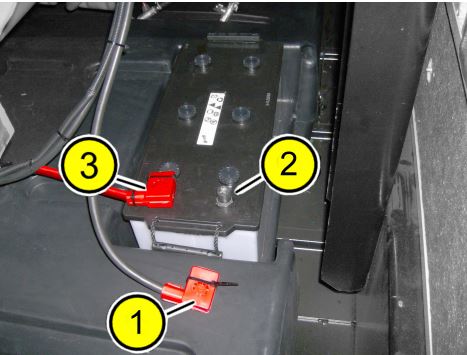

It is recommended to check the battery poles (2 and 3) and the electrolyte level every 15 days. If the poles (2 and 3) show signs of corrosion, remove it using ammonium diluted with water and a hard brush. Once the corrosion has been removed and the terminals reconnected, lubricate the poles with suitable grease. If the generator remains idle for a long time (more than 30 days), disconnect the poles of the battery to keep it from discharging. Always disconnect the negative pole (2) first and then the positive pole (3).

Checking the connections:

Make sure that the electric connection cables are firmly fixed to the connection terminals; tighten the screws if necessary.

Checking the windings:

The condition of the windings can be determined by measuring the earth insulation resistance.

Checking the bearings and alternator maintenance:

Refer to the supplied alternator manual before performing any operation on the alternator. If in doubt contact us.

Check and top up the engine oil level following the specific instructions for the engine model present on the generator. Refer to the documentation of the manufacturer of the engine before performing any operation on it.

Checking the engine oil level:

Topping up the engine oil:

Refer to the supplied manual of the engine to change the engine oil and the oil filter.

This task might be complex, if you require assistance, you can always contact one of our engineers – we’re here to help.

Verify and top up the coolant referring to the supplied manual of the engine.

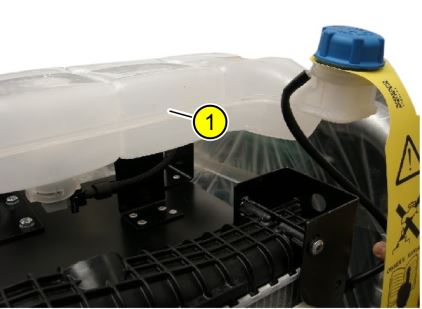

Location

In OPEN SET generators, the coolant tank is normally positioned above the radiator and can be accessed directly from the side of the engine, as shown in the photo with number (1) (purely indicative) (the shape and colour of the tank could differ depending on the version of the generator).

In SOUNDPROOF generators, the coolant tank can be reached by opening the filler cap (2) located on top of the bonnet.

Checking the level of coolant

Topping up the coolant

Changing the coolant

Replace the coolant filter referring to the supplied use and maintenance manual of the engine.

Replacing the coolant filter:

Replace the coolant filter as outlined in the engine’s user and maintenance manual. If you’re unsure or need expert assistance, it’s always best to contact GCM for professional support.

Replace the air filter while referring to the supplied use and maintenance manual of the engine.

Replacement:

Replace the filter while referring to the supplied use and maintenance manual of the engine. Even though for complex tasks or to ensure optimal performance, we recommend reaching out to one of our qualified engineers for professional assistance.

Replacing the fuel pre-filter:

Replacing the fuel filter

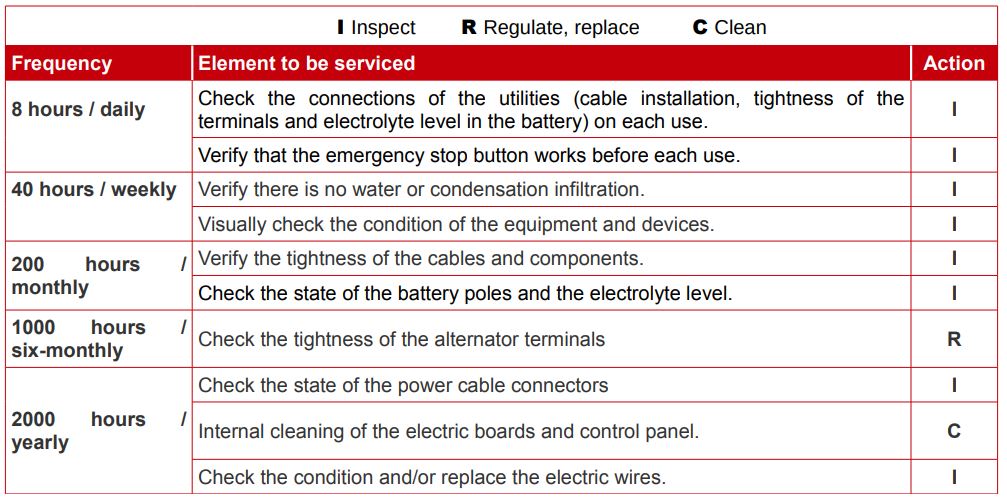

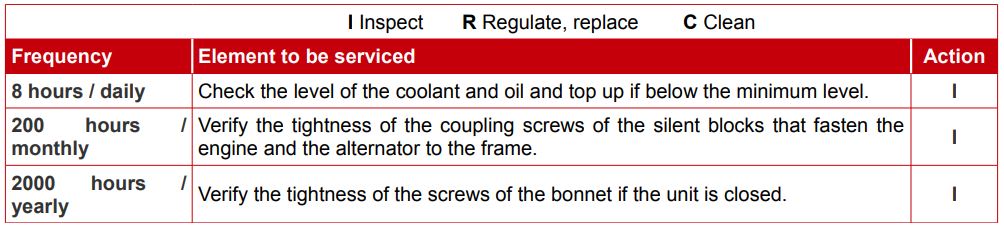

The maintenance interventions are divided between those on the electrical system and those on the mechanical parts. All the interventions are summarised in the following tables forming part of the routine maintenance schedule of the generator.

The maintenance schedule is based on an average use. If the engine is activated in adverse conditions, such as heavy prolonged loads or high temperatures, or used in unusually humid or damp conditions, contact the dealer for recommendations applicable to every single requirement and use.

Please refer to the engine’s provided use and maintenance manual for detailed instructions. If further expertise is required, don’t hesitate to contact our professional engineers for support.

Incorporating these generator maintenance tips into your routine ensures your equipment remains reliable and efficient. Regular upkeep not only prevents unexpected breakdowns but also extends the lifespan of your generator, saving your business time and costs in the long run. For expert generator maintenance services, or if you need assistance with any issues, emergencies, or scheduling maintenance, contact us today to keep your power systems running smoothly.

WE’RE ALL ENGINEERS HERE…

We only work with a group of tried and trusted suppliers and use the most reliable and effective equipment – which doesn’t always mean the most expensive. And, as controls and systems are continually changing, we keep abreast of all the latest developments to provide you with robust long-term solutions.