Industrial Generators

Optimise Your Business with Industrial Generators

Industrial Generators and Industrial Control Systems: Benefits, Components and Maintenance

Industrial Generators

Safeguard your business. Get in touch for a consultation.

At Generator Control and Maintenance Ltd, we specialise in providing high-performance industrial generators that deliver reliable power for your business. Whether you operate in manufacturing, construction, data centers, or other power-intensive sectors, our industrial generators are engineered to keep your operations running smoothly and efficiently.

Our range of industrial generators includes options for both diesel and natural gas, ensuring that you find the right fit for your energy requirements. We understand that downtime isn’t an option, which is why we offer robust, reliable solutions designed to perform in the toughest environments.

You get access to expert support, remote monitoring options, and preventive maintenance plans to keep your industrial generators operating at peak performance.

When the power fails, we won’t.

Switchgear

maintenance

Industrial Control Systems

Industrial control systems are vital for managing and automating complex processes across industries. These systems ensure the smooth and efficient operation of equipment like industrial generators, minimising downtime and optimising performance. By integrating advanced technologies, industrial control systems allow businesses to monitor and control power systems in real time, reducing risks and improving reliability.

Key benefits of industrial control systems include:

- Enhanced precision in monitoring and control.

- Improved energy efficiency and system reliability.

- Seamless integration with industrial generator servicing protocols.

- Reduction in unplanned downtime through predictive analytics.

For industries reliant on industrial generators, these systems play a crucial role in ensuring uninterrupted operations. Whether you’re managing large-scale power systems or critical backup generators, investing in modern industrial control systems helps maintain consistent performance while mitigating risks.

Industrial Generator Maintenance

Effective industrial generator maintenance is essential for ensuring the reliability and longevity of your equipment. Routine servicing prevents unexpected failures, reduces repair costs, and maintains operational continuity. Regular industrial generator servicing involves a thorough inspection and testing of components, ensuring optimal performance under all conditions.

Maintenance services typically include:

- Fuel system checks and cleaning.

- Inspection and servicing of cooling systems.

- Testing and calibration of industrial control systems.

- Load bank testing to verify generator capacity.

- Comprehensive industrial generator repair when required.

A proactive approach to industrial generator maintenance ensures that your power systems are ready when you need them most. By incorporating advanced diagnostics and predictive maintenance strategies, businesses can reduce downtime, enhance efficiency, and extend the life of their industrial generators.

Industrial Generators, Control Systems and Maintenance

At Generator Control & Maintenance Ltd, we provide end-to-end services for industrial generators, from installation to ongoing industrial generator maintenance and advanced industrial control systems integration. Our solutions are designed to keep your business powered, efficient, and prepared for any operational demands.

Our range of industrial generators offers dependable backup power, ensuring continuous operation during outages. We offer customised options to fit specific power needs, with models that are fuel-efficient, durable and designed for heavy-duty industrial use.

To maximise the performance of your power systems, our industrial control systems bring precise automation and monitoring capabilities. We install and maintain PLCs, HMIs and other advanced control components that enable real-time monitoring, predictive maintenance alerts, and energy management, ensuring seamless operation and optimised energy usage.

Regular industrial generator maintenance is key to preventing unexpected breakdowns and prolonging equipment lifespan. Our maintenance packages cover essential inspections, fuel and control system checks and performance diagnostics, allowing your industrial generators to operate at peak efficiency. With Generator Control & Maintenance Ltd by your side, you get reliable support for all your power needs, ensuring that your industrial generators and industrial control systems are always ready to perform.

Why Choose Generator Control & Maintenance Ltd for Your Industrial Power Needs?

When it comes to industrial generators, industrial control systems and industrial generator maintenance, Generator Control & Maintenance Ltd stands out as the trusted partner for businesses across sectors. Here’s why our clients rely on us for all their power and control needs:

Expertise and Experience: With years of industry experience, we specialise in delivering tailored solutions for industrial generators that meet the highest standards of durability and efficiency. Our team has extensive knowledge of industrial control systems and how to seamlessly integrate them into your power infrastructure, enhancing your operations.

Comprehensive Maintenance Solutions: We offer a full suite of industrial generator maintenance services, from routine checks to emergency support. Our proactive maintenance ensures that your equipment remains reliable, reducing the risk of unexpected breakdowns and extending the lifespan of your generators.

End-to-End Service: From selecting the right industrial generator to ongoing maintenance and control system upgrades, we provide complete solutions under one roof. Our commitment to excellence means we stay ahead with the latest technologies in industrial control systems, bringing you innovative features that improve performance and reliability.

Choosing Generator Control & Maintenance Ltd means partnering with a team that understands the demands of industrial power. Let us keep your business powered and protected with our reliable industrial generators, precision industrial control systems, and dedicated maintenance support.

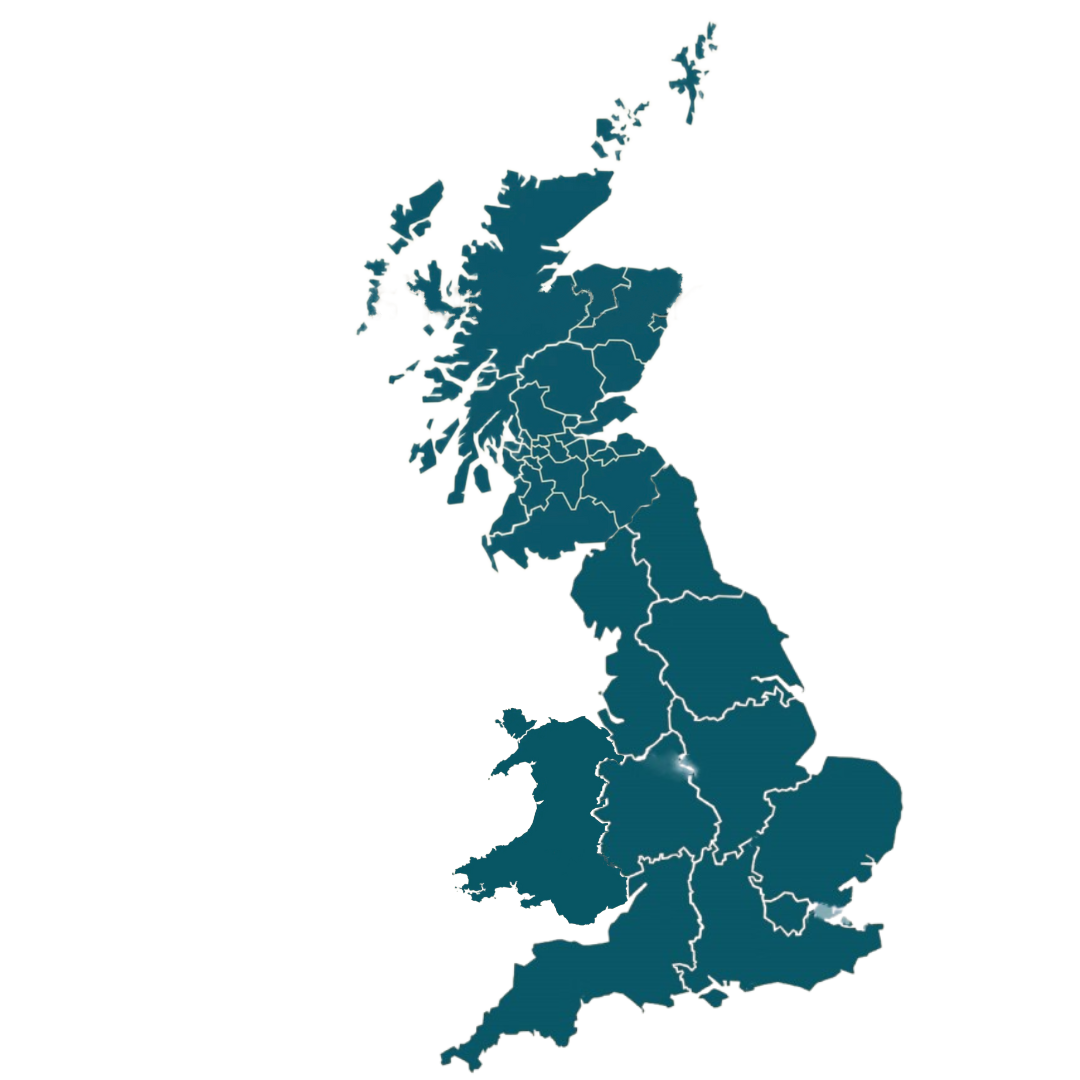

North East England

Yorkshire And The Humber

North West England

West Midlands

- Herefordshire

- Shropshire

- Staffordshire

- Warwickshire

- Worcestershire

East Midlands

East Of England

- Bedfordshire

- Cambridgeshire

- Essex

- Hertfordshire

- Huntingdonshire

- Norfolk

- Suffolk

South East England

Greater London

South-West Scotland

- Ayrshire

- Dumfries and Galloway

- Wigtonshire

- Renfrewshire

- Lanarkshire

- Dunbartonshire

Central Scotland

- Edinburgh

- Glasgow

- Stirlingshire

- Kinross-shire

- Fife

- Clackmannanshire

- Perthshire

North-East Scotland

- Aberdeenshire

- Aberdeen

- Banffshire

- Moray

- Dundee

Wales

- Clwyd

- Dyfed

- Gwent

- Mid Glamorgan

- Powys

- South Glamorgan

- West Glamorgan